Introduction to PVA Fiber: A Game-Changer in Cementitious Composites

Polyvinyl Alcohol (PVA) fiber has emerged as a leading enhancing material in modern cement-based compounds, reinventing the efficiency and resilience of concrete frameworks. Recognized for its high tensile strength, exceptional bond with concrete matrices, and remarkable resistance to alkaline settings, PVA fiber is at the leading edge of advanced fiber-reinforced concrete (FRC) modern technology. Its assimilation into ultra-high-performance concrete (UHPC), crafted cementitious compounds (ECC), and strain-hardening cementitious materials (SHCM) marks a significant jump towards ductile, crack-resistant, and lasting building and construction solutions.

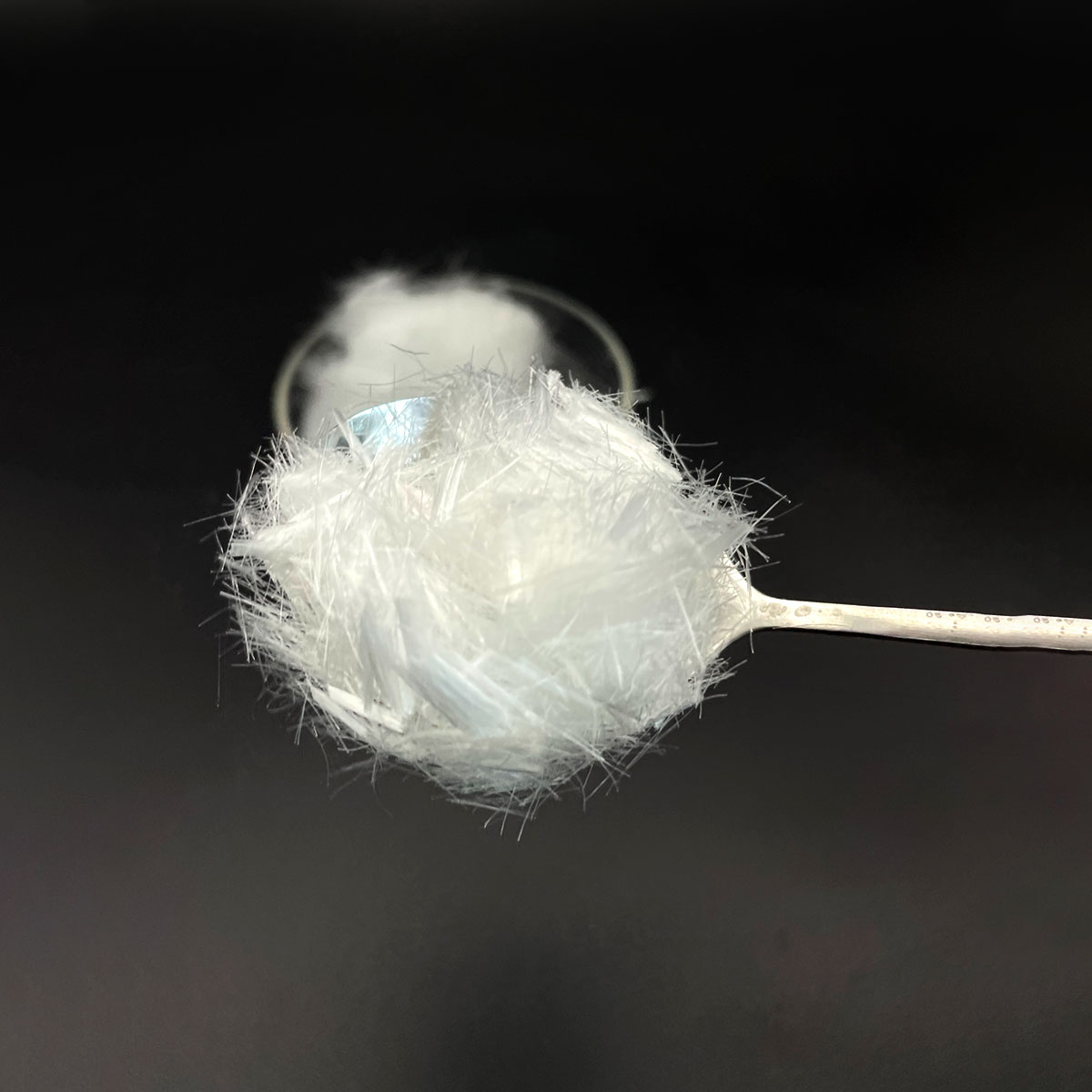

(PVA Fiber)

Chemical and Mechanical Features of PVA Fiber

PVA fiber is an artificial polymer defined by high hydrophilicity, modest modulus of flexibility, and strong interfacial bonding with cementitious products. Unlike steel fibers, which are vulnerable to deterioration, or polypropylene fibers, which supply limited mechanical support, PVA fibers incorporate versatility with strength– displaying tensile strengths going beyond 1,600 MPa and prolongation at break around 6– 8%. Their microstructure allows for reliable fracture bridging, energy dissipation, and post-cracking ductility, making them suitable for applications requiring sturdiness and impact resistance without endangering workability.

Device of Fracture Control and Ductility Improvement

The main feature of PVA fiber in concrete is to manage microcrack breeding and improve post-cracking actions. When consistently distributed within the matrix, PVA fibers serve as micro-reinforcement aspects that connect fractures started during loading or shrinking. This device substantially enhances flexural stamina, fracture toughness, and power absorption ability. In Engineered Cementitious Composites (ECC), PVA fibers allow strain-hardening actions, where the material exhibits numerous great cracks as opposed to tragic failing. This unique home simulates the ductility seen in steels, changing typically brittle concrete right into a quasi-ductile material appropriate for seismic-resistant and fatigue-prone structures.

Applications in Infrastructure, Fixing, and Prefabricated Systems

PVA fiber-reinforced concrete is increasingly utilized in framework jobs requiring high durability and durability. It plays an essential role in passage cellular linings, bridge decks, water control structures, and blast-resistant structures because of its capacity to withstand spalling under severe conditions. In architectural repair service and retrofitting, PVA-modified mortars offer enhanced adhesion, decreased contraction splitting, and enhanced lasting performance. Upreared parts incorporating PVA fibers take advantage of controlled breaking, dimensional stability, and quicker demolding cycles. Furthermore, its compatibility with automated spreading processes makes it fit for modular and 3D-printed building and construction systems.

Sustainability and Environmental Perks

Past mechanical performance, PVA fiber contributes to lasting building techniques. By allowing thinner, lighter, and longer-lasting frameworks, it lowers general material consumption and personified carbon. Contrasted to steel fiber-reinforced concrete, PVA fiber eliminates worries related to corrosion discoloration and galvanic rust, expanding service life and reducing upkeep prices. Some formulas now integrate bio-based or partially biodegradable versions, straightening with green building criteria and circular economic climate concepts. As environmental laws tighten, PVA fiber provides a sensible option that balances structural stability with ecological responsibility.

Obstacles and Limitations in Practical Implementation

Regardless of its benefits, the fostering of PVA fiber encounters difficulties associated with set you back, diffusion, and healing level of sensitivity. PVA fibers are more costly than standard artificial fibers, limiting their use in budget-sensitive applications. Attaining uniform diffusion needs specialized blending methods, as incorrect handling can bring about balling or segregation. Additionally, PVA fibers are delicate to long term wet-dry biking, which may affect lasting bond efficiency if not adequately resolved with fiber surface area therapy or hybrid fiber techniques. Addressing these concerns requires ongoing research study right into cost-effective manufacturing approaches and performance optimization.

Innovations Driving Next-Generation PVA Fiber Technologies

( PVA Fiber)

Recurring developments in fiber engineering are increasing the capacities of PVA fiber in construction. Surface area adjustment strategies such as plasma treatment, etching, and coating with nano-silica or polymer layers are boosting fiber-matrix interaction and toughness. Crossbreed systems combining PVA with other fibers– such as carbon or basalt– are being checked out to maximize mechanical properties throughout various filling situations. Researchers are also creating wise PVA fibers embedded with noticing capacities for real-time architectural wellness monitoring. These developments are pushing the limits of what fiber-reinforced concrete can accomplish, leading the way for smart, adaptive building materials.

Market Fads and International Market Outlook

The global market for PVA fiber in building is growing gradually, driven by enhancing need for high-performance concrete in Asia-Pacific, The United States And Canada, and Europe. Federal governments and industry leaders are purchasing resilient infrastructure, disaster reduction, and lasting metropolitan development– essential motorists for PVA fiber adoption. Leading chemical and building product providers are expanding product lines, boosting technological support, and working together with scholastic institutions to fine-tune application protocols. Digital tools such as AI-driven mix design software and IoT-enabled fiber dosing systems are more improving application, boosting efficiency, and making sure regular quality throughout large tasks.

Future Prospects: Combination with Smart and Resilient Building Ecosystems

Looking ahead, PVA fiber will certainly play a main function fit the future generation of clever and resilient building and construction ecological communities. Integration with digital twin platforms will allow engineers to mimic fiber-reinforced concrete actions under real-world problems, enhancing design prior to implementation. Advances in self-healing concrete incorporating PVA fibers and microcapsules are anticipated to extend structural life-spans and decrease lifecycle expenses. Additionally, as the building and construction sector accepts decarbonization and automation, PVA fiber sticks out as an essential enabler of lightweight, high-strength, and environmentally receptive building products customized for the future.

Vendor

Cabr-Concrete is a supplier of Concrete Admixture under TRUNNANO with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high quality high strength pva fiber, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

Tags: pva fiber,polyvinyl alcohol fiber, pva concrete

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us